Custom Drying and Granulation Machines

Jiangsu Xiandao can provide custom service for three kinds of products such as drying machines, granulating machinery and extraction and concentration equipment:

1) Drying machines

Different forms of material to be dried: powder, particle material, block material, flaky material, slurry, paste material, solution etc.

Material features: combustible material, explosive material, aggregate material, smelly material etc.

Drying methods: continuous drying, intermittent drying, dynamic drying, static drying, hot air drying etc.

The material requirements of the users on the drying equipment: stainless steel, titanium material, aluminum alloy, carbon steel, glass lining etc.

2) Granulating machinery

Granulating methods: granulating with dry rolling compactor, granulating with fluid bed, granulating with spray dryer, rotary granulating, oscillating granulating etc.

The required appearance of the finished products: cylindrical, globular, microporous spherical, triangular, rhombic etc.

The granulating target: improve the solubility, fluidity, reduce flying dust, provide compressed volume, coat, paint etc.

3) Extraction and concentration equipment

Extraction methods: negative pressure, ordinary pressure, positive pressure etc.

Material to be extracted: plant, animal, Chinese medicine, food additives and some other thermos-sensitive material.

1. Multiple solutions

Jiangsu Xiandao has 30 years of industrial experiences. We have provided solutions for customers from different industries such as pharmaceutical industry, food industry, chemical industry, ceramic industry, battery material industry, bio-engineering industry etc.

2. International suppliers

1) Jiangsu Xiandao search for suitable suppliers around the world to improve product quality.

2) Until now, we have established long term cooperation with famous suppliers such as Siemens from Germany, Honeywell from USA, Riello and APV from Italy, Netsch from Germany, Feluwa from Germany etc.

3. Strict product manufacturing and quality control

1) Our company has five exclusive factories which are respectively responsible for the manufacturing of air heater, atomizer, metal plate and parts, particles and dust separator, electrical control system.

2) We carry out strict quality control from product design, purchasing, manufacturing to product delivery.

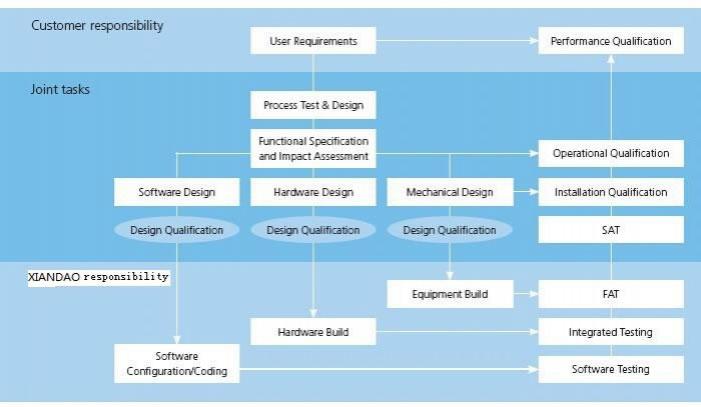

1) User requirement specification (URS)-the customers will express requirements on product performance, technique, using and service.

2) Design qualification (DQ)-the customers will confirm whether the equipment selected by us can meet the standardized requirements.

3) Factory acceptance test (FAT)-to ensure that all the index of the equipment can meet the customers’ requirements, before the delivery of the finished products, we will carry out specific inspection of the equipment performance, technical parameters and configurations. After the test, the customers should sign the factory acceptance record.

4) Site acceptance test (SAT)-according to the contract, we will carry out SAT at the position of our customers. If the customers choose to do acceptance in our factory, we will conduct packaging and transportation after debugging and confirmation from our customers.

5) Installation qualification (IQ)-after the installation, we will test all the systems of the machine and files related to the machine.

6) Operation qualification (OQ)-various operational test will be carried out to ensure that the equipment can meet the targeted requirements.

7) Performance qualification (PQ)-we will carry out pilot production of the equipment to ensure the production requirements of our customers.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.