- Home

- Products

- Spray Dryer

- Closed cycle Spray Dryer

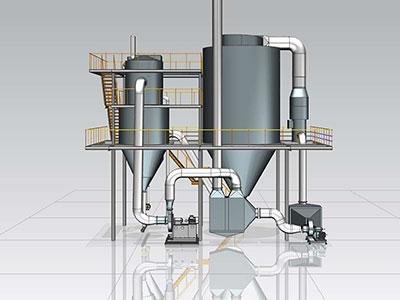

Closed cycle Spray Dryer (Inert N2 Gas Sealed System)

This type of spray dryer is operating in gaseous Nitrogen as an inert medium circulating in a closed cycle within all the equipment.

Closed Cycle Spray Dryer for hard metals

Closed Cycle Spray Dryer for hard metalsThe spray dryer with closed circulation drying system works under enclosed environment. The drying requires inert gas which is generally nitrogen.

The closed circulation drying system is mainly used for drying of material containing alcohol or flammable and combustible solvent or material which can be easily oxidized so that it should not contact the air. By filling with nitrogen and some other inert gases, this dryer can protect the material from air.

The product produced by this dryer can be used to produce spherical material so that this dryer is suitable for production of high precision ceramic, tungsten carbide, silicon nitride, nano-ceramics, cemented carbide and some other powders, medicinal intermediate etc.

| Item | BYP-8 | BYP-12 | BYP-16 | BYP-20 | BYP-25 | BYP-30 | BYP-35 |

| Ethyl alcohol evaporation quantity | 4kg/h | 8kg/h | 11kg/h | 19kg/h | 28kg/h | 41kg/h | 55kg/h |

| Drying room dimension | Φ800 | Φ1200 | Φ1600 | Φ2000 | Φ2500 | Φ3000 | Φ3500 |

| Ancillary facilities | Manhole, inspection window, illuminating window | ||||||

| Atomizer | WH-50 | WH-65 | WH-65 | WH-65 | WH-84 | WH-120 | WH-120 |

| Speed (r.p.m) | 10000~36000 | 7000~30000 | 7000~30000 | 7000~30000 | 7000~25000 | 7000~21600 | 7000~21600 |

| Product recovery | Single or two point recovery | ||||||

| Material pump volume | 6L/H | 15L/H | 20L/H | 30L/H | 40L/H | 80L/H | 120L/H |

| Heating source | Electrical heating | Hot kerosene (or electric heater) | |||||

| Electrical heating power | 6.5KW | 15KW | 26KW | 30KW | 45KW | 60KW | 84KW |

| Max hot air temperature | 200℃ | 200℃ | 200℃ | 200℃ | 200℃ | 200℃ | 200℃ |

| Ancillary devices | Circulating fan, cyclone separator, bag filter, solvent recovery unit | ||||||

| Instrument control | Hot air temperature CNC instrument, temperature recording, cyclone separator, bag filter differential pressure gauge, tower pressure gage etc. | ||||||

| Safety device | Oxygen concentration detector, pressure switch, automatic system pressure adjusting system | ||||||

| Installed power | ~12KW | ~26KW | ~33KW | ~45KW | ~60KW | ~90KW | ~120KW |

Note: The evaporation quantity of the ethyl alcohol use the quantity when the hot air inlet temperature is 140℃ and the outlet temperature is 70℃ as a baseline.

If you are interested in a specific type of spray dryer with closed circulation drying system listed above, you can tell us the No. of the equipment and if you need related adjustment on the configuration. If you need more pre-drying and post-drying equipment, Jiangsu Xiandao can satisfy your requirements. If there is no existing dryer which can meet your demands, please tell us your requirements. And we can provide more solutions according to your needs.

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.