Spray Cooler

The spray drying system cooler can conduct atomization of melted fluid in the cooling room and then cool down the fluid drop with normal or low temperature air so that the liquid will be solidified into spherical particles. Now, this system is widely used in chemical, food, pharmaceutical industries.

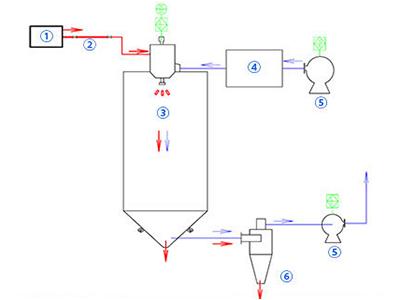

① Material/feed liquid

② Compressed air of 1-2 Bar1-2

③ Drying tower

④ Compressed air or dehumidified air

⑤ Fan

⑥ Cyclone

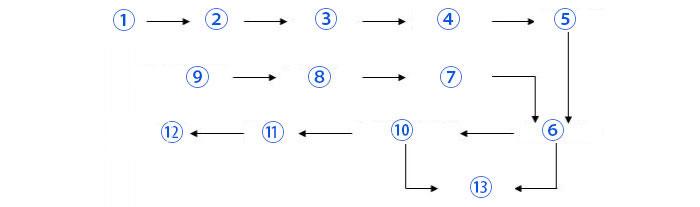

① External air

② Filter

③ Unit cooler

④ Air dehumidifier

⑤ Air distributor

⑥ Cooling and granulating tower

⑦ Centrifugal atomizer

⑧ Insulating material feeding pump

⑨ Melted liquid raw material

⑩ High efficiency cyclone separator

⑪ Exhaust fan

⑫ Exhaust gas emptying

⑬ Product collection

Jiangsu Xiandao can not only provide related granulating machinery according to your specific requirements, we can also provide related supporting equipment such as drying equipment, coating equipment etc. If you have interest on our machines, please tell us your demands, we will provide you with complete solution and perfect after-sale service.

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.