Flash Dryer

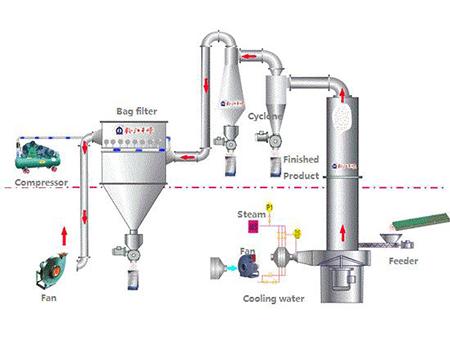

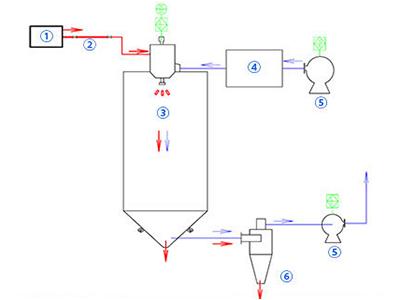

Flash dryer combines drying, milling and classifying, with inlet gas temperatures up to 600°C or even higher. It is suitable for sticky and cohesive materials, usually filter cakes, slurries. In a flash dryer, wet material is dispersed into the drying air-steam then heated to the particles. Since the flash drying system only removes surface moisture, final products will maintain the physical and chemical properties.

| specification | Barrel diameter(mm) | Main machine dimensions(mm) | Main machine power(kw) | air velocity(m³/h) |

| XSG-2 | 200 | 250×2800 | 5-9 | 300-800 |

| XSG-3 | 300 | 400×3300 | 8-15 | 600-1500 |

| XSG-4 | 400 | 500×3500 | 10-17.5 | 1250-2500 |

| XSG-5 | 500 | 600×4000 | 12-24 | 1500-4000 |

| XSG-6 | 600 | 700×4200 | 20-29 | 2500-5000 |

| XSG-8 | 800 | 900×4600 | 24-35 | 3000-8000 |

| XSG-10 | 1000 | 1100×5000 | 40-62 | 5000-12500 |

| XSG-12 | 1200 | 1300×5200 | 50-89 | 10000-20000 |

| XSG-14 | 1400 | 1500×5400 | 60-105 | 14000-27000 |

| XSG-16 | 1600 | 1700×6000 | 70-135 | 18700-36000 |

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.