- Home

- Products

- Fluid Bed Dryer

- Fluid Bed Granulator/Pelletizer/Processor

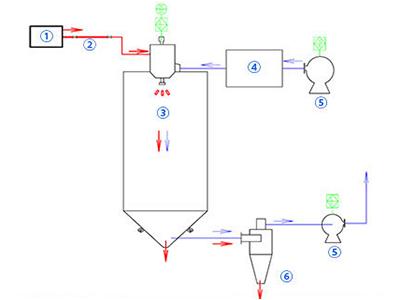

FL Series Fluid Bed Granulator/Pelletizer/Processor

The granulator with fluid bed realizes the combination of machine design and preparation technology. Jiangsu Xiandao provided more than one hundred sets of granulators for customers from China, USA, Japan, Indonesia and Iran. The granulators are all specially designed according to the material features and process requirements.

Granulating in pharmaceutical industry

Granulating in food industry

Granulating in other industries

Drying of powder or particle wet materials

The following are the granulator types which have been produced by JiangSu Xiandao. You can also make some improvements on the base of the specific types:

| Item | Unit | Type | ||||||||||

| 3 | 5 | 15 | 30 | 60 | 120 | 200 | 300 | 500 | 1000 | |||

| Raw material container | Volume | L | 12 | 22 | 45 | 100 | 220 | 420 | 670 | 1000 | 1500 | 3000 |

| Diameter | mm | 300 | 400 | 550 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | 2200 | |

| Production capacity | Min | kg | 1.5 | 4 | 10 | 15 | 30 | 80 | 100 | 150 | 250 | 800 |

| Max | kg | 4.5 | 6 | 20 | 45 | 90 | 160 | 300 | 450 | 750 | 1200 | |

| Fan | Air quantity | m3/h | 1000 | 1200 | 1400 | 1800 | 3000 | 4500 | 6000 | 7000 | 8000 | 13670 |

| Air pressure | mmH2O | 375 | 375 | 480 | 480 | 950 | 950 | 950 | 950 | 950 | 1400 | |

| Power | kw | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 30 | 37 | 45 | 90 | |

| Steam consumption | kg/h | 15 | 23 | 42 | 70 | 141 | 211 | 282 | 366 | 451 | 750 | |

| Compressed air consumption | m3/min | 0.9 | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 1.1 | 1.5 | 3.0 | 4.0 | |

| Main machine weight | kg | 500 | 700 | 900 | 1000 | 1100 | 1300 | 1500 | 1800 | 2500 | 3500 | |

| Steam pressure | Mpa | 0.1-0.4 | ||||||||||

| Temperature | ℃ | Room temperature around-120℃, adjustable | ||||||||||

| Working time | min | Vary from 45-90 according to material features. | ||||||||||

| Material yield | % | ≥99 | ||||||||||

| Noise | dB(A) | The fan and main machine are installed separately so the noise≤75dB(A) | ||||||||||

| Outline dimension of the main machine | M | 1.0×0.6 ×2.1 | 1.2×0.7 ×2.3 | 1.25×0.9 ×2.5 | 1.6×1.1 ×2.5 | 1.85×1.4 ×3 | 2.2×1.65 ×3.3 | 2.34×1.7 ×3.8 | 2.8×2.0 ×4.5 | 3×2.25 ×5.0 | 4×2.8×7.2 | |

The granule produced by this granulator with fluid bed is easily dissolved with rapid speed. This granulator has multiple functions of mixing, granulating and drying.

This equipment adopts pressure relief hole which can ensure the safety of the equipment and operators. This is an anti-explosion granulator.

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.