- Home

- Products

- Tablet Coater, Drum coater

- Fluid Bed Tablet Coater

Fluid Bed Tablet Coater

The fluid bed tablet coater is widely used for powder granulating and powder, granule coating.

| Item | Machine type | |||||||||||

| Name | Unit | 3 | 5 | 10 | 15 | 30 | 60 | 90 | 120 | 200 | 300 | 500 |

| Feeding quantity | Kg/ batch | 3 | 5 | 10 | 15 | 30 | 60 | 90 | 120 | 200 | 300 | 500 |

| Fan power | Kw | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 | 22 | 30 | 55 |

| Compressed air quantity | m3 /min | 0.25 | 0.35 | 0.55 | 0.6 | 0.85 | 1.1 | 1.1 | 1.3 | 1.8 | 2.4 | 3 |

| Steam consumption | Kg/h | 36 | 40 | 50 | 70 | 95 | 145 | 165 | 180 | 340 | 380 | 450 |

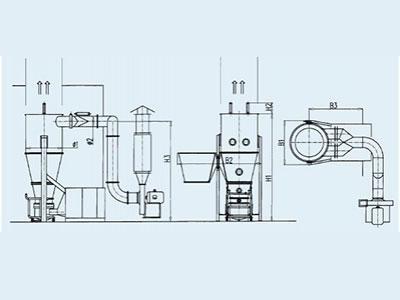

| Installation dimension for reference | H 1 (mm) H 2 (mm) H 3 (mm) Ø1(mm) Ø2(mm) B 1 (mm) B 2 (mm) B 3 (mm) | 1950 310 1750 400 150 660 1200 880 | 2360 310 2030 550 180 1050 1650 950 | 2400 250 2100 550 180 1010 1560 1100 | 2500 320 2200 700 250 1160 1830 1250 | 2500 340 2200 700 250 1160 1830 1250 | 3050 490 2750 1100 280 1460 2460 1530 | 3050 540 2750 1100 280 1460 2460 1530 | 3050 590 2750 1200 280 1660 2860 1650 | 3450 680 3150 1400 280 1860 3260 1650 | 3650 790 3350 1600 315 2030 3660 1750 | 4000 890 3700 1800 355 2260 4060 1850 |

The fluid bed tablet coater has the function of material mixing, granulating and drying. This single machine can realize the functions which should be realized by many different equipment sets. So the processing flow can be reduced and the labor cost and production cost of the company can also decline. This coater is manufactured according to GMP standards. It is mainly used for production of material featuring bad fluidity and bad hygroscopicity. The product produced by this coater is porous, easily dissolved and features relatively high hardness. If you are interested in certain type of the fluid bed tablet coater, please tell us the specific model. There will be someone who is responsible to contact you. If there is no coating machine which can meet your requirements, you can tell us your demands. And we will make improvements on the base of the existing types so that it can meet your requirements.

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.