- Home

- Products

- Extraction and Concentration System

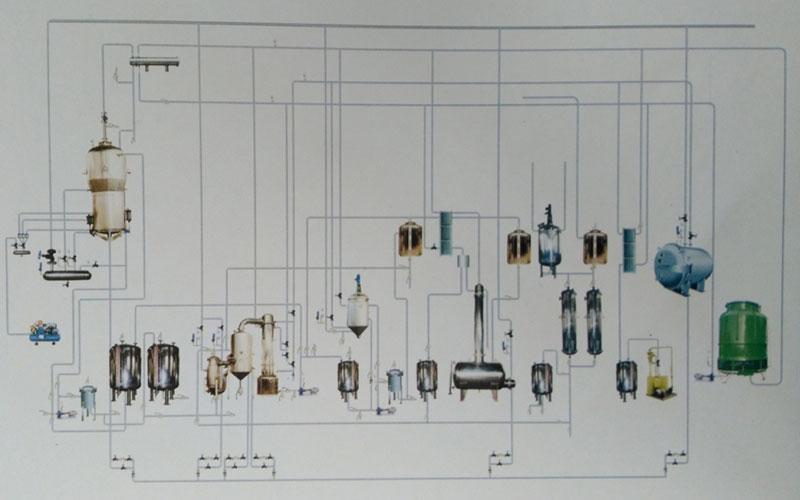

- Traditional Chinese Medicine Extraction and Concentration Line

Traditional Chinese Medicine Extraction and Concentration Line

The dynamic extraction line for traditional Chinese medicine is energy and water saving. It can shorten the time of extraction, concentration and drying. The whole set of line meets the GMP standard requirements so it is suitable to be used in large, medium and small pharmaceutical factory and hospital preparation room.

| Type | STQ-50G | STQ-100G | STQ-200G | STQ-300G |

| Item | ||||

| Extraction method and temperature | Water to be added (L/batch) | |||

| Raw material treating capability (KG/batch) | 50 | 100 | 200 | 300 |

| Water to be added (KG/batch) | 500 | 1000 | 2000 | 3000 |

| Extraction time | 2 h/batch, the time recording is started from that the water temperature of the extraction tank is up to the requirements. | |||

| Solid-liquid separation method | Centrifugal separation | |||

| Residue discharging method | Mechanical scraping | |||

| Concentration method | Continuous three way energy saving vacuum concentration | |||

| Concentration speed (KG/h) | 300 | 500 | 1000 | 1500 |

| Water evaporation capability of spray drying (KG/h) | 30 | 60 | 120 | 180 |

| Moisture content of dry extract (%) | 3 | |||

The dynamic extraction line for traditional Chinese medicine consists of the following units:

- Extraction unit

- Solid-liquid separation unit

- Three-way energy saving concentrator

- Spray dryer

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.