- Home

- Products

- Tablet Coater, Drum coater

- Multifunctional Pellet Coater

Multifunctional Pellet Coater

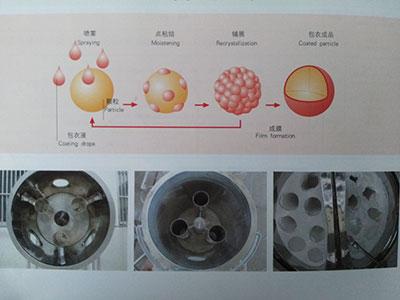

The multifunctional pellet coater is a new type of solid preparation production equipment combining the following techniques together: spray drying and granulating technique, fluid bed and spray fluid bed technique and rotary granulating technique. The top of the coater is responsible for spraying, granulating while the bottom of it is responsible for spray coating. This coater is suitable for granulating, pelleting and coating in industries such as traditional Chinese medicine, western medicine, food and chemical industry etc.

| Item | Unit | DLB-3 | DLB-5 | DLB-10 | DLB-15 | DLB-20 | DLB-30 | DLB-40 | DLB-60 | DLB-80 | DLB-120 | DLB-150 | DLB-200 | DLB-300 | DLB-500 | ||||

| Top spraying container volume | 1 | 15 | 22 | 35 | 45 | 70 | 100 | 180 | 210 | 320 | 410 | 560 | 660 | 1100 | 2000 | ||||

| Bottom spraying container volume | 10 | 15 | 26 | 35 | 55 | 90 | 115 | 145 | 235 | 320 | 425 | 535 | 900 | 1600 | |||||

| Tangent spraying container volume | |||||||||||||||||||

| Top spraying capability | Kg/batch | 1.5~4.5 | 5 - 15 | 10-30 | 15-60 | 20-80 | 230-110 | 40 - 150 | 60-220 | 80 - 300 | 120-380 | 150-550 | 200-750 | 300-1000 | 500-1500 | ||||

| Bottom spraying capability | Kg/batch | 1.2-3.6 | 5 - 12 | 10-25 | 15-45 | 20-65 | 30-110 | 40 - 120 | 60-170 | 80 - 200 | 120-280 | 150-360 | 200-480 | 300-850 | 500-1200 | ||||

| Tangent spraying capability | Kg/batch | 0.6-2.0 | 2.4 - 8 | 4-20 | 6--48 | 8-60 | 12-80 | 14- 100 | 20-120 | 24 - 150 | 40-200 | 60-280 | 100-360 | ||||||

| Induced draft fan power | Kw | 3.0 | 4.0 | 4.5 | 5.5 | 7.5 | 7.5 | 18.5 | 22.0 | 28.5 | 35.5 | 42.5 | 48.5 | 55 | 75 | ||||

| Auxiliary fan power | Kw | 0.55 | 1.5 | 1.5 | 2.2 | ||||||||||||||

| Electrical heater power | Kw | 7.5 | 21 | 22.5 | 27 | 31 | 42.5 | 51.5 | 81.0 | 105 | 135 | 145 | 175 | 234 | 315 | ||||

| Steam consumption | Kg/h | 25 | 60 | 85 | 100 | 120 | 180 | 195 | 220 | 280 | 360 | 400 | 480 | 600 | 1000 | ||||

| Steam pressure | MPa | 0.40 C 0.60 | |||||||||||||||||

| Compressed air consumption | M³/h | 0.25 | 0.35 | 0.7 | 0.6 | 0.9 | 0.85 | 1.1 | 1.3 | 1.5 | 1.8 | 2.0 | 2.2 | 3.0 | 4.0 | ||||

| Compressed air pressure | MPa | 0.40 C 0.60 | |||||||||||||||||

| Working temperature | ℃ | Automatically adjusting according to room temperature-120℃ | |||||||||||||||||

| Material temperature | ℃ | Automatically adjusting | |||||||||||||||||

| Equipment noise | dB | < =70 | |||||||||||||||||

| Whole machine weight | KG | 1200 | 1450 | 1650 | 1800 | 2350 | 2600 | 2950 | 3450 | 3650 | 4000 | 4450 | 5000 | 6500 | 8000 | ||||

| Size | A1 | A2 | A3 | B | C | ΦD | E1 | E2 | G |

| 5 | 3210 | 3210 | 2810 | 2140 | 920 | 500 | 3260 | 2610 | 740 |

| 15 | 4060 | 4060 | 3660 | 2280 | 970 | 800 | 4100 | 3410 | 970 |

| 30 | 4400 | 4400 | 4000 | 2520 | 1130 | 1200 | 4600 | 3750 | 1420 |

| 60 | 4800 | 4800 | 4400 | 2900 | 1180 | 1400 | 5000 | 4100 | 1620 |

| 120 | 5100 | 5100 | 4700 | 3000 | 1380 | 1500 | 5300 | 4400 | 1620 |

| 300 | 5760 | 5760 | 5490 | 3465 | 1840 | 1800 | 6500 | 5090 | 1990 |

| 500 | 6630 | 6630 | 6360 | 4145 | 2145 | 2700 | 7590 | 5960 | 2960 |

The multifunctional pellet coater produced by JiangSu Xiandao can be used for granulating and coating in traditional Chinese medicine, western medicine and chemical industries. Some product types are listed in this page, if there is one which meets your requirements, you can tell us the No. of it. We can provide you with detailed information of this type. If there is no type of product which can meet your requirements, you can directly tell us your demands so that we can provide you with improved design. JiangSu Xiandao not only provides whole set of drying equipment, granulating equipment and coating equipment, we also provide perfect after-sales services.

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.