- Home

- Products

- Spray Dryer

- Rotary Atomizer

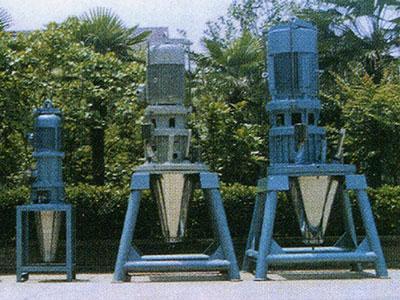

Rotary Atomizer

The rotary spray drying atomizer should ensure the uniform size of the fog drops so that it can produce powder which can meet the standards and requirements. The selection of atomizer is decided by the raw material features and specification of the product to be dried. Normally, we give priority to rotary spray drying atomizer because of the better flexibility and easy operation.

The rotary spray drying atomizer is suitable for raw material easy to be wear and tear. It can realize rapid material feeding without blocking. This product can adopt low pressure material feeding system of which the rotation speed can be easily adjusted. So the fog drop size can be controlled.

Three kinds of atomizer used in industrial production:- Rotary spray drying atomizer: centrifugal energy caused atomization

- Pressure nozzle atomizer: pressure energy caused atomization

- Two-fluid nozzle atomizer: kinetic energy caused atomization

| Spray type | High speed rotary atomizer | ||||

| Atomizer speed (r/min) | 25000 | 18000 | 16000 | 12000-13000 | 11000-12000 |

| Atomizing diameter (mm) | 50 | 102 | 108 | 180-210 | When the water evaporation is over 2000 kg/h, the atomizing diameter is decided according to process requirements. |

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.