- Home

- Products

- Spray Dryer

- Lab Spray Dryer

- Multifunctional Lab Spray Dryer

Multifunctional Lab Spray Dryer

There are three spraying methods for this multifunctional lab spray dryer:

1. Rotary atomizer which is installed at the center of the tower top uses 6Pa compressed air to realize atomization. This atomizer can conduct drying of particles of which the diameter is 5-25μm. The atomizer with impeller is suitable for anti-corrosion material while the atomizer with tungsten carbide liner is suitable for corrosive material.

2. The two fluid atomizer which is installed at the center of the tower top uses 0.5~2.0Pa compressed air to realize atomization. The raw material and compressed air are separately sent to the atomizing nozzle for atomization. The two fluid atomizer is suitable for treating relatively thick material. This mode is suitable for drying of heat sensitive material of which the particle size if from 5-25μm.

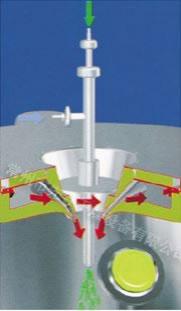

3. The fountain type atomizer is installed at the bottom of the tower, carry out spraying from the bottom. This mode can provide best heat utilization efficiency for the drying equipment. It can also realize longer residence time of the material inside the tower. The diameter of the powder particle which can be dried is from 15-80μm. This atomizer is suitable for processing of powder with good fluidity, drying of fine ceramics and non-heat sensitive material.

Inlet air temperature control: 50~350℃

Outlet air temperature control: 50~100℃

Water evaporation: 1~5kg/h

Atomization method: centrifugal or two fluid nozzle atomization

Temperature control precision: ±1℃

Whole machine power: ~10KW/380V

If you are a medical institution or laboratory, this multifunctional lab spray dryer can satisfy your drying requirements. Please tell us the material to be dried and its specification, we can recommend matching dryer according to your requirements.

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.