- Home

- Products

- Spray Dryer

- Lab Spray Dryer

- Closed Cycle Lab Spray Dryer

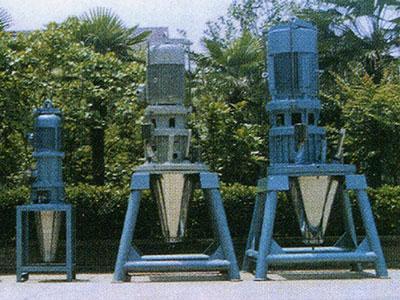

Closed Cycle Lab Spray Dryer

The closed cycle lab spray dryer is suitable for drying of material containing combustible solvent or releasing toxic gas during drying. It is suitable for material which is quite sensitive to drying temperature because it can conduct low temperature drying under 100 ℃.

This is a kind of safe and energy saving lab spray dryer because:

This lab spray dryer adopts closed cycle structure. It also adopts inert gas as the drying medium so that the drying can be safer.

The drying medium can be used repeatedly to reduce medium consumption.

The heat in the tail gas can recycled and reused via heat exchanger to save energy.

Drying room specification: Φ1200×H800

Atomization method: centrifugal atomization

Atomizer speed: 7000~30000r.p.m (adjustable)

Inlet air temperature: 180~200℃ (adjustable)

Outlet air temperature: 60~90℃ (adjustable)

Water evaporation: 15kg/h (when inlet air temperature is 200℃, and outlet air temperature is 90℃.)

Hot air contacting: co-current

Heating source: electrical heating

Feeding pump: peristaltic pump

Product capturing: cyclone separator single point

Power source: 3 phase 5 line; 380V/50Hz; ~25kw

Main machine outline specification (reference value): L3200×W2500×H3000

Electrical control panel code: anti-explosion and explosive proof

Control mode: PLC+HMI

If the target material will release toxic gas or explosive gas after being heated, the closed cycle lab spray dryer is an ideal choice. This drying equipment adopts closed cycle structure and anti-explosion design to ensure the safety of operators and equipment.

Besides the drying equipment, Jiangsu Xiandao can also provide related supporting equipment according to the requirements of the processing site. If you have interest on our drying equipment, please contact us, we will provide you with satisfying processing machine and complete after-sales service.

We are a specialist in the design and manufacturing of fluid bed dryer/granulator, spray dryer and other processing equipment for a variety of industries. Our company is established in 1965. Our design consistently meets our customers’ expectations for product quality, cost efficiency and low maintenance costs. According to the business requirements of our clients’ industry, we can provide full service such as drying and granulation production line design, manufacturing, installation, training and aftersales maintenance. Up to now, we have provided numbers of successful projects in different industries involving pharmaceutical industry, food industry, chemical industry, and agro alimentary industry. We understand what you need and know how to execute the project. We can partner with you to ensure compliance, contact us today.

-

- JIANGSU XIANDAO DRYING SCI-TECH. CO., LTD. is a joint stock enterprise focusing on the research, development, design and manufacturing of spray dryers and fluid bed dryers.